When it comes to future-forward thinking, small innovations can lead to sizable results for manufacturers. The growing digital transformation in manufacturing has changed the game for the industry. Customer expectations, regulatory requirements, and geopolitical conditions are only a few factors that have turned up the heat on digital transformation.

We’ll talk about what manufacturers can do to walk into the future employing digital transformation efforts, and where some areas for opportunity currently exist.

What is Digital Transformation in Manufacturing?

Digital transformation has become a buzz term, but it has very practical applications in manufacturing. When manufacturing businesses engage in digital transformation, they’re adding digital technologies into different parts of the manufacturing process to improve product development, inventory management, and the customer experience, for example.

Companies may use technologies such as artificial intelligence (AI), Internet of Things (IoT) devices, cloud computing, and machine learning (ML) to transform their manufacturing operations.

Why Should Manufacturers Implement Digital Transformation?

Embracing digital technologies used to be optional for manufacturers, but changing expectations from customers has made digital transformation more of a requirement. If manufacturers expect to remain competitive and thrive in a new digital marketplace, they must implement and grow their business using new digital pathways.

The call to implement digital transformation has become more urgent in recent years due to geopolitical changes, shifts in productivity, customer expectations, sustainability requirements, new technologies, and more.

Geopolitics Drives Relocation and Production

Reshoring, nearshoring, and friendshoring are all supply chain trends that have shaken up manufacturing production. Reshoring involves bringing production back to home countries, nearshoring is about moving production to nearby countries, and friendshoring is where manufacturers shift production to political or economic allies.

While some of this moving and shifting can improve proximity for production, other moves will make it more necessary for manufacturers to implement remote monitoring and management to keep tabs on their operations from afar. Trade wars, tariffs, and labor unrest can also be causes for change in production environments.

Decreased Productivity Due to Skilled Labor Shortages

It’s projected that there will be 2.1 million unfilled manufacturing jobs by 2030, mainly due to shortages in skilled labor. The Census Bureau says that diversity, equity, and inclusion (DEI) initiatives can help fill jobs over time, but what can manufacturing businesses do now to cope with the current shortages?

Digital transformation can help improve productivity by implementing tools and technologies that automate everyday tasks, reducing the number of skilled workers needed for regular operations. Manufacturers should also focus on upskilling their current workforce.

Sustainability Requirements

Sustainable manufacturing is still in its early stages, but big box retailers and regulatory bodies alike have started to adopt certain standards for manufacturers and supply chain vendors. For example, the Sustainability Accounting Standards Board (SASB) offers industry-specific standards that can help manufacturers better report on their sustainable efforts. ISO 14001 is an international standard for environmental management systems (EMS) that manufacturers can use to evaluate their environmental impact.

As these standards move from optional to required, manufacturers that have digital transformation tools in place can more easily implement sustainable measures that ensure compliance, as well as set them apart from competitors who have not yet set sustainable business goals.

AI and Digital Tech Broadens Competition

When manufacturers operated more regularly out of part lists and catalogs, business competition had more to do with immediate territory. Vendors would form referral networks and build relationships to grow their business. However, the rapid expansion of digital technologies, including AI, has democratized innovation and made the manufacturing landscape more competitive.

As manufacturers make it easier for customers to order from states, or even countries, away, businesses need to improve their operations, production processes, and customer experiences to remain competitive and reach new customer segments.

Customer Expectations

Customer expectations for manufacturing companies were different not too long ago. The manufacturing industry needs to work on closing the experience gap – the gap customers may feel between the quality of the product and the service experience. Customers aren’t just looking for products anymore. They’re hungry for experiences.

Privacy and Security Concerns

Privacy and security have become major concerns for all industries, manufacturing included. Sector leaders expect supply chain threats to grow in the coming years. Application-specific breaches have contributed to almost half of all attacks. As manufacturing businesses increase their reliance on digital technologies, their complex digital makeup can increase concerns around cybersecurity and data privacy.

8 Benefits of Digital Transformation in Manufacturing

We’ve come a long way from paper directories and part lists. Today, the manufacturing industry is experiencing rapid transformation through the embrace of new digital technologies. These tools can improve internal operations, as well as upgrade the experience for consumers and partners alike. The following are 8 of the top benefits manufacturers can expect along their digital transformation journey.

Data Visibility

Before digital tools introduced a world of possibilities, manufacturers could only hope to gain insights about the production floor through their physical presence. Digital transformation empowers manufacturers with real-time visibility on all operations, including the production floor, the supply chain, and more.

Data visibility can be great for real-time tracking as well. By improving visibility, manufacturers can have a better idea of what’s in their supply chain at any given time and what they can do to optimize the flow of goods. Real-time availability data can also help prevent stock shortages, as well as minimize excess inventory.

Operational Predictability

Imagine being able to predict problems before they start affecting your operations. That’s what data analytics and predictive maintenance can do for the manufacturing industry. By forecasting potential issues, digital transformation tools can improve consistency, reduce costs, and keep downtime at all-time lows.

Enhanced Operational Efficiency

Not only can digital transformation help manufacturers make predictions with better accuracy, but it can also improve operational efficiency by streamlining previously manual processes. Machine learning, artificial intelligence, and other automation tools can reduce the likelihood of human error, save time on repetitive tasks, and open time up for team members to focus on more sophisticated topics.

Improved Quality Control

The human eye can only spot so much. Machine vision and artificial intelligence can serve as digital technologies that can spot inconsistencies and defects that can be hard to identify. When configured properly, these technologies can cut down on scrap and reworking time.

Elevated Customer Experience

Digital transformation projects can work on many sides of improving the customer experience by personalizing product recommendations, tracking the status of an order with greater accuracy, or offering real-time support. When manufacturing businesses elevate the customer experience, they build stronger relationships and can improve the likelihood of repeat business.

Reduced Time-to-Market

Digital tools and technologies can speed up the time it takes to bring a new product to market, creating greater efficiencies for product development, prototyping, and testing. They can both speed up the development cycle itself and the time between cycles so that manufacturers can respond more quickly to new demands. These improvements can give manufacturing businesses the competitive edge necessary to continue to grow in the market.

Better Regulatory Adaptability

Reducing the time-to-market is just one example of how digital transformation can make manufacturers more adaptable to changing conditions. Regulatory standards is also changing rapidly. Pivoting to a digital-first framework can help businesses pivot more quickly and meet these evolving requirements for matters such as data protection, IT safety, and environmental impact.

Decreased Costs and Increased Margins

All of the factors above can reduce costs greatly across different elements of the manufacturing process. Inventory management can reduce spend. Predictive maintenance can reduce downtime and reduce the amount of times equipment needs to be replaced. Improving the customer experience can reduce costs associated with acquiring new customers. As businesses iterate on manufacturing improvements using digital transformation tools and technologies, costs will go down and profit margins will go up.

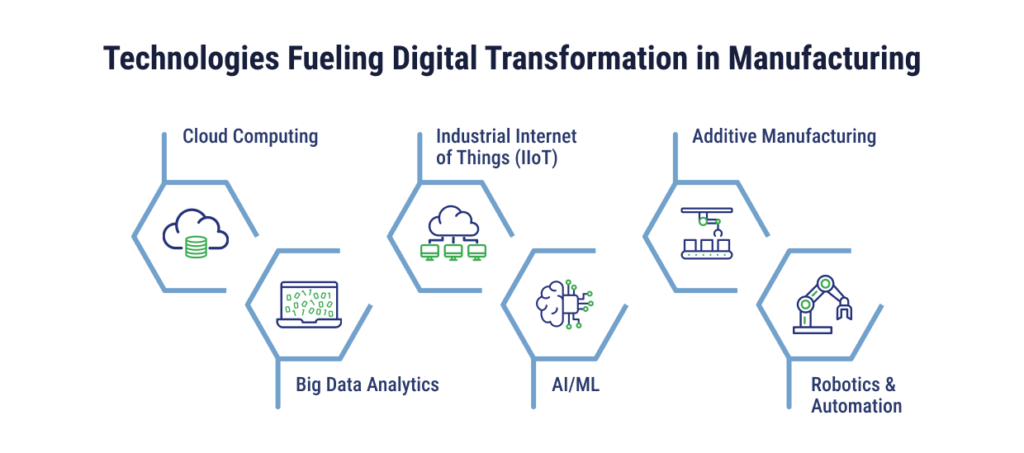

Key Technologies Driving Digital Transformation in Manufacturing

Many different digital technologies offer opportunities for businesses to engage in rapid digital transformation, including cloud computing, big data, artificial intelligence, robotics, and more. While it can be daunting to think about the many different options available, what’s most important is that manufacturers start by choosing one avenue for innovation.

Cloud Computing

Cloud computing technologies will continue to open up new possibilities for the manufacturing industry. Instead of managing on-premise data centers and having to choose software and systems that are coded specifically for these servers, manufacturers can now migrate to the cloud and take advantage of cloud-based software as a service (SaaS) tools.

Businesses that invest in cloud-enabled digital transformation projects can become more cloud agnostic with time, meaning they can operate applications, services, and tools seamlessly across multiple cloud platforms instead of relying on just one. Cloud manufacturing can be used to manage product lifecycles, supply chain flows, and production processes, to name a few.

Big Data Analytics

Big data is reaching numbers beyond human comprehension. By 2025, it is estimated that humans will create more than 181 zettabytes of data, or 181 followed by 21 zeroes worth of data. Currently, all of the data available online would take a person 180 million years to download.

The manufacturing industry generates a tremendous amount of data. This can include machinery sensors, customer feedback, and business intelligence insights on delivery routes. Unless this data is used and analyzed, manufacturers run the risk of repeating mistakes, often costly ones.

Cloud-based analytics tools and digital technologies using AI/ML can form insights faster, allowing manufacturers to pivot more quickly and improve key elements of the production, delivery, and customer experience realms.

Industrial Internet of Things (IIoT)

While IoT devices have worked their way into many people’s homes, industrial Internet of Things (IIoT) devices have also become more prominent. IIoT devices can connect industrial assets to the internet, such as machinery, devices, and sensors. Interconnected devices can help manufacturers collect and exchange real-time data that feeds into predictive analytics, environmental controls, inventory management, and more.

AI and ML

When we talk about automation, AI and ML play significant roles in automating manual tasks. However, AI/ML can also create intelligent systems and allow manufacturers to make faster decisions by analyzing data and uncovering patterns that may otherwise have gone unnoticed. Businesses with a lot of historical data can use it to train ML models that can improve processes over time by making suggestions that optimize manufacturing processes and improve product quality.

Additive Manufacturing

Additive manufacturing is more popularly known as 3D printing. Through additive manufacturing, businesses can create customized and more complex products on demand, allowing for greater freedom and reducing waste. 3D printing can also spin up rapid prototypes or produce things that are much more complicated for traditional methods to handle. One innovative way additive manufacturing is being used currently is in the prosthetics industry, where custom-made products are vital for comfort and performance.

Robotics and Automation

Robotics and automation can work alongside AI/ML technologies to repeat tasks and improve precision. They may either be used on their own or as a collaborative tool with human workers to make processes more safe and efficient. Digital transformation in robotics and automation can look like programming tasks, optimizing process flows, and lending a hand in packaging, palletizing, and quality control, among other things.

How to Facilitate Digital Transformation in Manufacturing

Manufacturing businesses looking to facilitate digital transformation need to develop a comprehensive strategy that uses a data-driven approach to make choices on technology adoption, as well as organizational change management to ensure projects run smoothly.

Businesses shouldn’t simply start digital transformation efforts because certain tools or technologies are trending. They should, instead, understand how different solutions can improve their business, bolster their compliance, and elevate the customer experience. Manufacturers should also identify metrics before starting digital transformation projects that can track the before-after success of new initiatives.

Build a Solid Digital Transformation Strategy with TierPoint

A successful digital transformation starts with a strong foundational strategy. For organizations in the manufacturing industry, navigating the complexities of digital transformation is imperative to remaining competitive and achieving operational excellence. TierPoint’s tailored cloud services coupled with our IT advisory services empower organizations to confidently plan and execute a solid digital transformation strategy.

Need help navigating your journey to the cloud? Download our eBook to learn how you can minimize risks while maximizing the benefits of cloud adoption.

FAQs

Digital technology in the manufacturing industry can improve customer experiences, optimize the production process, simplify complex supply chain issues, and enable greater innovation in shooter time frames.

Digital transformation in manufacturing is moving forward thanks to a few main technological drivers, including artificial intelligence, machine learning, the Industrial Internet of Things, cloud computing, robotics, and additive manufacturing.

To implement a digital transformation process in manufacturing, the most important thing to keep in mind is how certain digital technologies will improve parts of the business. Manufacturers shouldn’t be implementing new digital transformation projects just because something is trending.