May 14, 2025 | Matt Pacheco

Moving Beyond Air: The Perks of Liquid Cooling in Data Centers

Consumer demands on data centers are growing at a breakneck speed, with the proliferation of AI, edge computing devices, and 5G-enabled technologies that require high-performance computing. An effective data center cooling solution is necessary to keep the equipment that powers these technologies operational and free from damage. While traditional air cooling methods are still used in some scenarios, they are not well-suited to support high-density workloads.

Liquid cooling has emerged as a modern solution to the challenge of data center cooling, providing many advantages, including greater sustainability, lower costs, and the ability to handle greater power densities for more complex workloads. We’ll cover why data centers are moving beyond air and harnessing the perks of liquid cooling.

The Challenges of Air Cooling in Modern Data Centers

As data centers become packed with more powerful hardware, they encounter new challenges and limitations with air cooling. When it comes to high-density workloads, air cooling can be less effective than liquid cooling. This is because air has a lower capacity to carry heat away.

What is Liquid Cooling?

Liquid cooling is a technique for absorbing and removing heat from IT equipment, like servers, using liquid, usually either water or a specialized coolant. There are different approaches data centers may use with liquid cooling, but, in general, this method is more well-suited for high-density hardware.

From the same temperature increase, water can absorb and transport more heat, making it a more efficient choice for modern data centers.

Benefits of Data Center Liquid Cooling Over Air Cooling

Making changes can be a costly and complex undertaking, so it’s important to ask, is air cooling better than liquid cooling in data centers? In modern, high-performance environments, data centers can experience improved energy efficiency, heat density capacity, and space efficiency. Tenants, in turn, can enjoy better reliability and performance, plus an increased hardware lifespan.

Enhanced Energy Efficiency

Because liquid cooling can remove more heat with less energy compared to air cooling, it’s inherently more energy efficient. This reduces operational costs and improves sustainability for data centers that make the switch.

Improved Heat Density Capacity

Data centers that support modern workloads will need to maintain more powerful processors configured in smaller spaces. Air cooling in tight spaces can be difficult or near impossible – generally, data centers require more space and more complicated airflow management systems to achieve cooling for high-density configurations. Liquid cooling can contend with a higher heat density in the same amount of space.

Elevated Reliability and Performance

Excessive heat on data center equipment can significantly impact its reliability and performance. Processors, for example, may experience thermal throttling, where they reduce clock speeds to prevent damage, hampering performance in the process. Excessive, repeated heat can also damage equipment and lead to premature failures. Because liquid cooling can produce more consistent and precise temperature controls, many performance and reliability problems related to air cooling are not a concern. High-density and resource-intensive workloads, like artificial intelligence (AI), machine learning, and advanced analytics, rely on peak performance to function effectively. This makes liquid cooling a necessity.

Increased Hardware Lifespan

Because liquid cooling mitigates damage associated with temperature fluctuations and thermal stress, components won’t fail as early and can experience longer lifespans. This reduces costs associated with hardware replacements, decreasing capital expenditures and cutting down on extraneous electronic waste.

Optimized Space Efficiency

Air cooling can require additional space, not just from the space between components, but also via air ducts and powerful fans. Liquid cooling reduces spatial requirements and allows for a more compact data center design, enabling data centers to house more equipment in the same physical footprint.

Components of a Liquid Cooling System

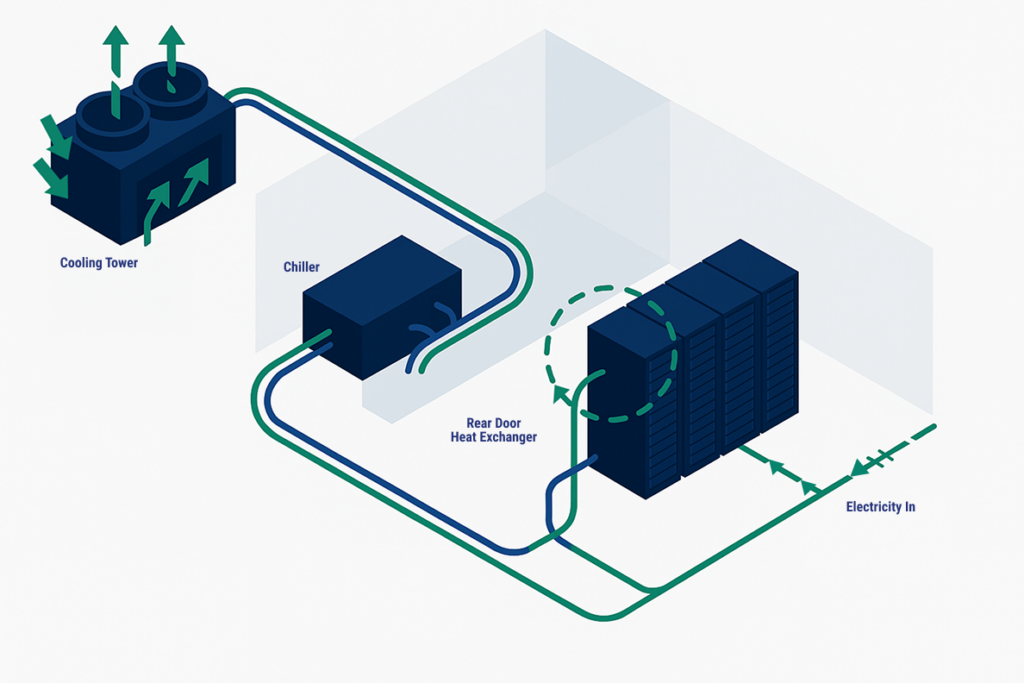

The benefits of liquid cooling systems are made possible with the following interconnected components:

- Coolant Distribution Units (CDU): These are at the center of the liquid cooling system and are responsible for moving the coolant throughout the data center, maintaining the needed pressure and flow rate for the system. CDUs can include control systems, heat exchangers, and pumps.

- Manifolds and Piping: Coolant is delivered to and from the IT equipment using an array of pipes and manifolds that are built to accommodate flow requirements and are made of leak-resistant materials.

- Cold Plates: Cold plates are used in direct-to-chip cooling to cool heat-generating components like CPUs and GPUs directly. These absorb heat right from the source.

- Heat Exchangers: Heat from warm coolant can be transferred to chilled water, the outside air, or another medium via heat exchangers, allowing the coolant to be cooled and circulated again.

- Pumps: Coolant is moved through the loop with pumps, which enable the cool and warm liquids to flow continuously.

- Coolant: Whether the coolant is water or a specific substance, this is used inside piping and chosen based on heat capacity and thermal conductivity, as well as its ability to meet performance standards.

- Sensors and Control Systems: These are used to monitor pressure, temperature, and flow rates of the liquid cooling system, and might be adjusted using intelligent control systems to change pump speeds, valve positions, and other configurations.

- Immersion Tanks: In the case of immersion cooling, servers are submerged in immersion tanks, where liquid absorbs heat directly, and then the heat is taken out of the tank with heat exchangers.

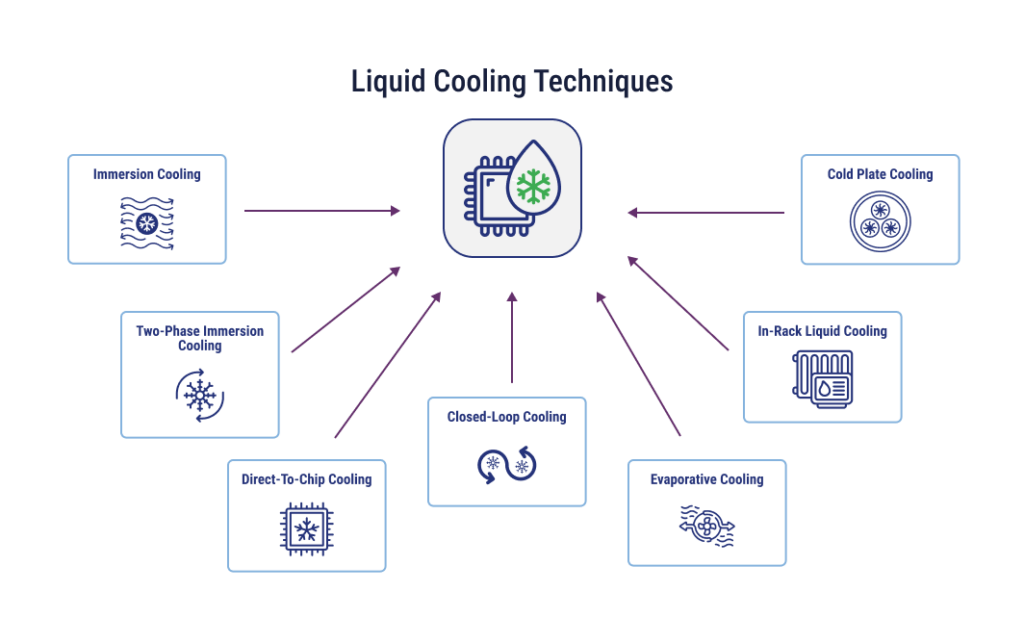

Seven Techniques for Liquid Cooling in Data Centers

Just as businesses use different workloads and equipment to execute business processes, data centers use different liquid cooling techniques to meet infrastructure, performance, and budget requirements.

Immersion Cooling

With immersion cooling, the IT equipment is submerged in a non-conductive liquid — a coolant that isn’t water. The liquid removes the heat from the hardware and components and then gets cooled in a heat exchanger. Data centers that prioritize extreme density and energy efficiency may opt for immersion cooling.

Two-Phase Immersion Cooling

This type of cooling takes advantage of a liquid’s phase change to remove heat from IT components.

As electric components begin to heat up, a fluid with a low boiling point and is non-conductive will begin to boil and vaporize. The rising vapor is then cooled and recondensed into a liquid, moving to the bottom of the tank and repeating the reheating cycle. The latent heat of vaporization is used in this method to remove the heat from the IT equipment.

This method takes the heat transfer methods from immersion cooling and takes them up a notch. Cutting-edge data centers that are pushing boundaries for power density may require this approach.

Direct-to-Chip Cooling

Also known as direct liquid cooling, direct-to-chip cooling circulates the liquid on the CPU or GPU and then passes the liquid through the heat exchanger to cool it back down before recirculation. Data centers that house a lot of CPUs and GPUs, perhaps for AI model training or scientific research, may want to harness this technique.

Closed-Loop Cooling

Closed-loop cooling is where coolant is pumped through a closed loop of tubing and pipes, often closely related to direct cooling. Workloads that recently benefited from air-cooled racks that are looking for more targeted cooling may choose to move to this method. These self-contained methods exist within a server and are similar to a large-scale version of what you might find in high-performance desktop PCs.

Evaporative Cooling

Evaporative cooling doesn’t directly cool IT equipment using liquid. Instead, evaporative cooling will cool water in a loop that will service other liquid cooling systems, such as cold plates and rear-door heat exchangers. This is done via evaporative condensers or cooling towers that use evaporation to remove heat from the loop.

Data centers that have relatively low humidity and are looking for energy-efficient ways to run a liquid cooling system may choose this option.

In-Rack Liquid Cooling

For a more specific closed-loop cooling environment, data centers may look to in-rack liquid cooling. All liquid cooling components in this system are going to be located within or next to a server rack and used for just that rack. Heat may be handled using heat exchangers with fans or sent to a secondary cooling loop. This can be a good choice for workloads that can benefit from a dedicated, specific cooling system.

Cold Plate Cooling

Cold plates, as mentioned above, are connected to a CDU, which circulates coolant and allows heat to transfer efficiently from CPUs and GPUs. A cold plate cooling method could be used in data centers with high-density racks where several servers are sharing one cooling loop.

Calculating the Impact of Liquid Cooling Efficiency

The impact of liquid cooling efficiency is truly seen in its quantitative benefits, including its power usage effectiveness, total usage effectiveness, and heat removal capacity. These measurements demonstrate the energy efficiency, cost savings, and improved sustainability that data centers can achieve with liquid cooling.

Power Usage Effectiveness

Power usage effectiveness (PUE) is calculated by taking the total amount of energy a data center uses and dividing it by the energy used to power the necessary IT equipment. The lower the PUE, the more efficient the data center is.

For example, an ideal number would be 1.0, but generally, most data centers have higher PUEs because of the energy costs of cooling, lighting, and other overhead expenses. Using a liquid cooling system can bring the PUE down.

Total Usage Effectiveness

Total usage effectiveness (TUE) is an expansion of PUE that looks at the energy efficiency of a data center overall. This includes how much energy is being used by infrastructure, IT equipment, and ancillary equipment. All aspects of the data center are included in this calculation, instead of just IT equipment. Again, the ideal TUE would be 1.0.

Heat Removal Capacity

Liquids used in cooling systems can have higher specific heat capacity and thermal conductivity than air.

Specific heat capacity is the amount of heat energy that is needed to increase the temperature of a substance’s unit mass by one degree Celsius. The specific heat capacity of water, for example, is about four times that of air.

Thermal conductivity measures the ability of a material, like a liquid coolant, to conduct heat. Water’s thermal conductivity is about 25 times that of air, meaning that heat will transfer more effectively in liquid coolant. The heat removed in a system can be found by considering the mass flow rate of the coolant, the heat capacity of the coolant, and the temperature difference between the hot liquid and how much it has been cooled.

How Liquid Cooling Enhances AI Workload Performance in Data Centers

Companies looking to enhance their workload performance in data centers, particularly for AI projects, should work with facilities that can accommodate higher power densities and live up to the heat removal capacities necessary to achieve optimal performance without damaging or straining equipment.

Liquid cooling technology is well-equipped to support these greater demands on data centers. For example, TierPoint offers state-of-the-art cabinets tailored to accommodate your high-performance GPU/AI compute needs and enhance your AI workload performance. These cabinets feature a closed-loop liquid cooling system, offering improved sustainability and efficiency compared to conventional air cooling and evaporative liquid cooling methods. Whether you’re exploring high-density or standard colocation services, or searching for managed cloud options, we’re here to help.

Learn more about our high-density colocation services and schedule a tour today.